CGI Ladle Production

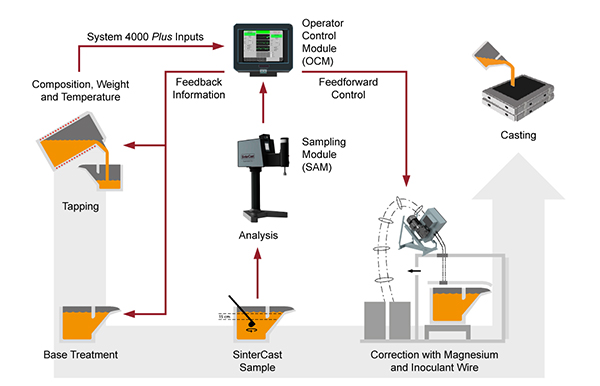

Process Control for Ladle Production: Measure-and-Correct

The ladle process begins by obtaining a sample of the base treated iron in the SinterCast Sampling Cup. This is a simple task that is typically performed by the forklift driver. Depending on the result of the thermal analysis, the wirefeeder is automatically instructed to add the necessary amount of magnesium and inoculant cored wires to bring the iron to the optimal start-cast conditions, and the operator is prompted to start the feeding. Pouring begins at the conclusion of wirefeeding. A typical magnesium corrective wire addition is approximately 25 grams per tonne. The entire on-line Measure-and-Correct process requires approximately three minutes and is conducted in parallel with standard foundry activities such as deslagging and ladle transport. The process allows for continuous operation of the moulding line at normal grey iron production rates.

The objective of the base treatment operation is to intentionally undertreat the iron such that, even if all factors combine to achieve the highest possible magnesium and inoculant recovery, the iron would only arrive at the start-cast coordinates. This allows precise wirefeeding additions to be prescribed without the risk of shrinkage defects or excess nodularity caused by overtreatment. Beyond overtreatment, the only operational requirement of the base treatment process is that the sampled iron is neither fully grey nor fully white.

Download PDF

- Technical Article: Process Control for the Production of Compacted Graphite Iron