Industrial Power

Beyond the core cylinder block and head market, the SinterCast technology has supported the production of a variety of components that range from 2.7 kg to 9 tonnes. These components have been used in rail, marine, construction, stationary power, and agriculture applications.

Cummins QSK Cylinder Head – Locomotive and Stationary Power Engines

Wabtec Cylinder Head – Locomotive and Stationary Power Engines

Caterpillar Cylinder Heads – Off-Road Applications

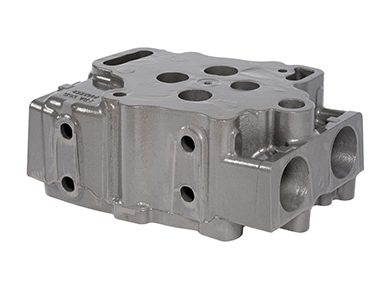

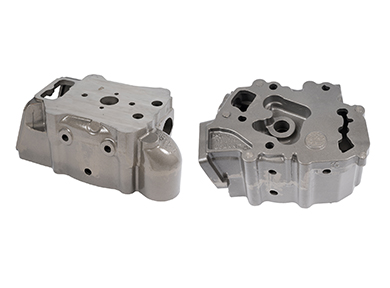

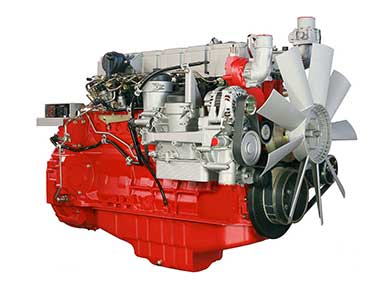

Deutz 7.8 Litre Cylinder Head – Agricultural and Construction Equipment

Industrial Power Engine Frames and Cylinder Heads – Allen Diesels, Cameron Compression, Jenbacher, MTU and Waukesha Engines

Large Cylinder Liners and Piston Rings – Marine and Stationary Power Engines